Har du noen gang lurt på hvordan anleggsutstyr beveger seg så jevnt og presist? Eller hvordan fabrikkmaskiner kan kontrollere hastigheten så nøyaktig? Svaret ligger ofte i en liten, men mektig komponent som kalles en hydraulisk strupeventil.

I denne guiden vil vi bryte ned alt du trenger å vite om hydrauliske strupeventiler på en enkel måte. Enten du er student, vedlikeholdsarbeider eller bare er nysgjerrig på hvordan ting fungerer, vil denne artikkelen hjelpe deg med å forstå disse viktige enhetene.

Hva er en hydraulisk gassventil?

En hydraulisk strupeventil er som en vannkran for hydrauliske systemer. Akkurat som du dreier på et kranhåndtak for å kontrollere hvor raskt vannet renner ut, kontrollerer en gassventil hvor raskt hydraulikkvæsken strømmer gjennom et system.

Enkel analogi:Tenk på det slik: Når du klemmer en hageslange, kommer det mindre vann ut, og det renner saktere. En hydraulisk strupeventil fungerer på samme måte - den skaper en mindre åpning som væsken må passere gjennom, noe som bremser strømmen.

Hvorfor er de viktige?

Hydrauliske strupeventiler er avgjørende fordi de:

- Kontroller hastigheten til hydrauliske sylindre og motorer

- Få maskiner til å bevege seg jevnt i stedet for rykk

- Hjelp operatører med å jobbe med presisjon

- Hold utstyret trygt ved å forhindre brå bevegelser

Hvordan fungerer en hydraulisk gassventil?

Vitenskapen bak gassventiler er faktisk ganske enkel. Det hele kommer ned til én grunnleggende idé: jo mindre åpningen er, jo langsommere flyt.

Her er hva som skjer inne i ventilen:

- Hydraulikkvæske kommer inn i ventilen under trykk

- Væsken må passere gjennom en liten åpning (kalt en åpning)

- Størrelsen på denne åpningen kan justeres ved å dreie på et håndtak eller en skrue

- Mindre åpning = langsommere flyt = langsommere maskinbevegelse

- Større åpning = raskere flyt = raskere maskinbevegelse

Den enkle matematikken bak

Ikke bekymre deg – vi blir ikke for tekniske her! Men det hjelper å vite at strømningshastigheten avhenger av tre hovedting:

Størrelsen på åpningen(større = mer flyt)

Trykkforskjellover ventilen (mer trykk = mer strømning)

Type væskeblir brukt

Ingeniører bruker spesielle formler for å beregne eksakte strømningshastigheter, men det grunnleggende prinsippet er lett å forstå.

Typer hydrauliske gassventiler

Akkurat som det finnes forskjellige typer kraner i hjemmet ditt, finnes det flere typer strupeventiler. Hver og en er designet for spesifikke jobber.

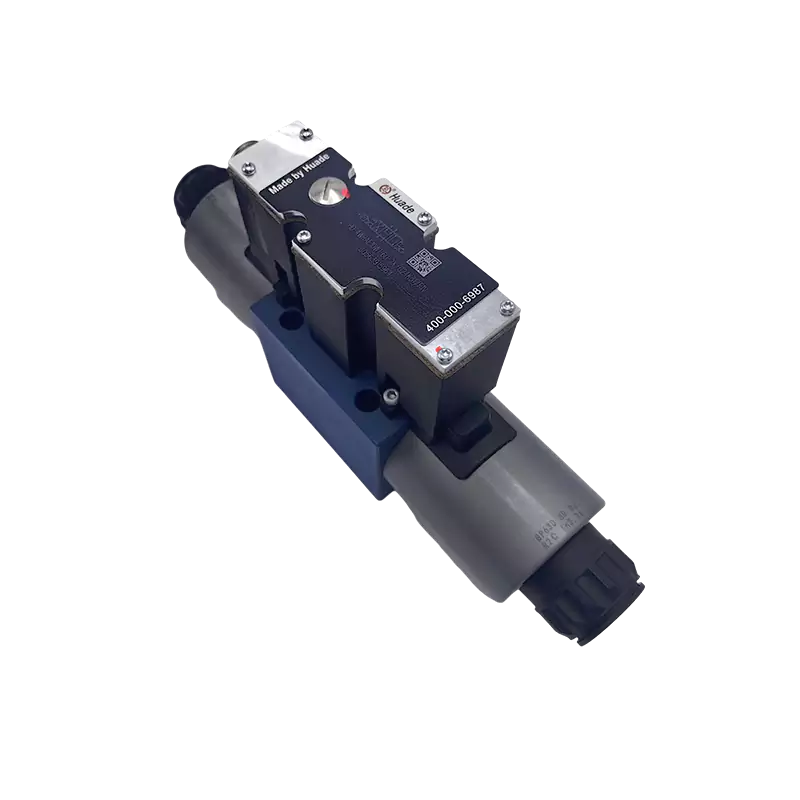

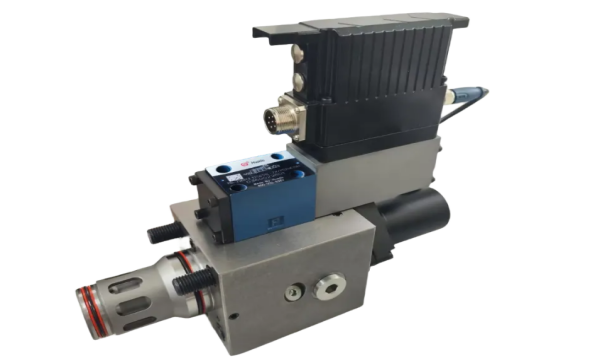

1. Nålgassventil

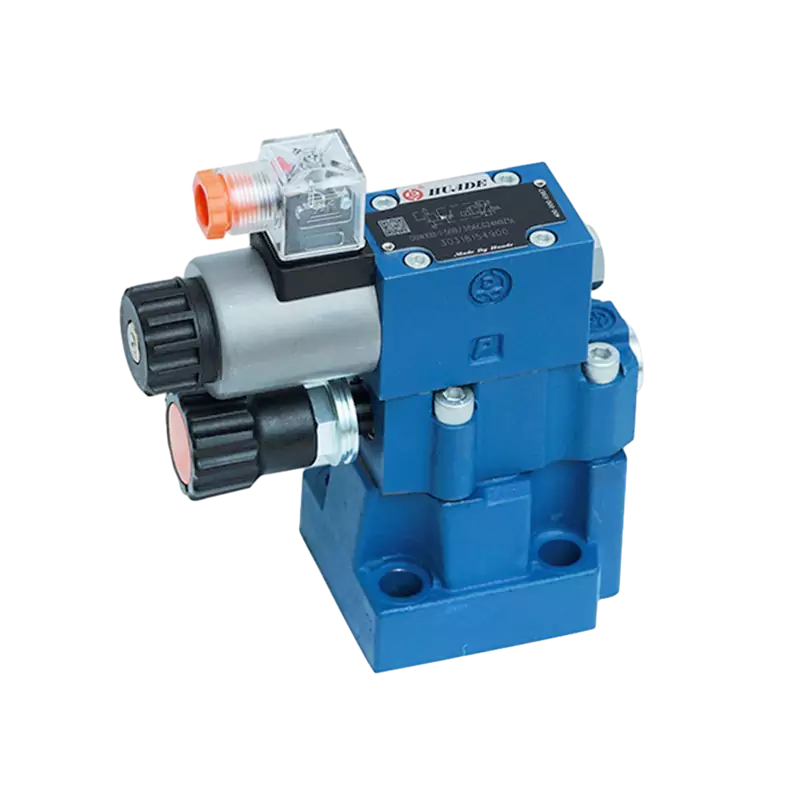

2. Eksentrisk gassventil

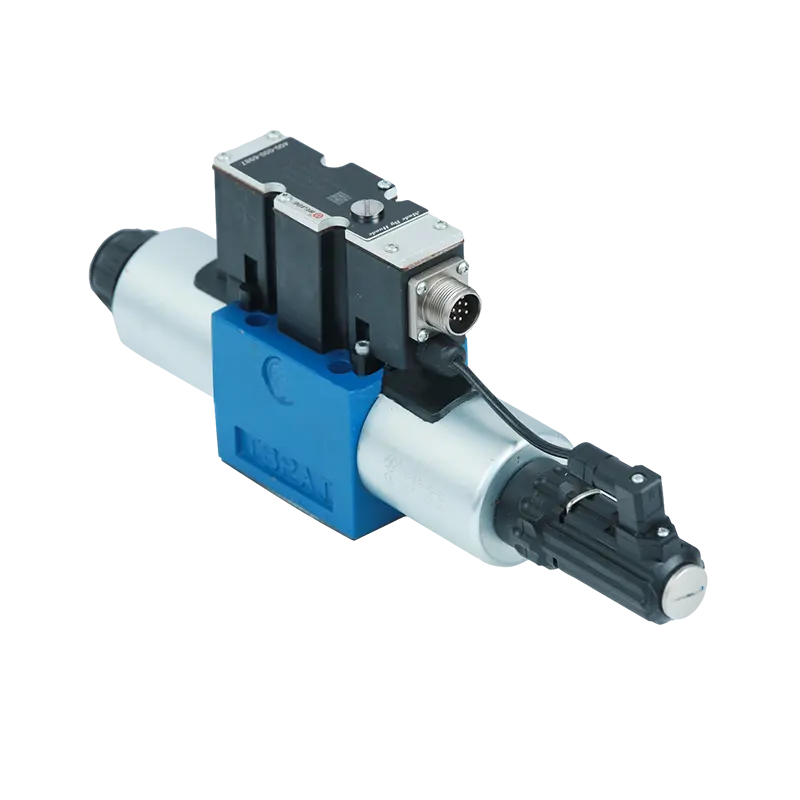

3. Aksial trekantet rilleventil

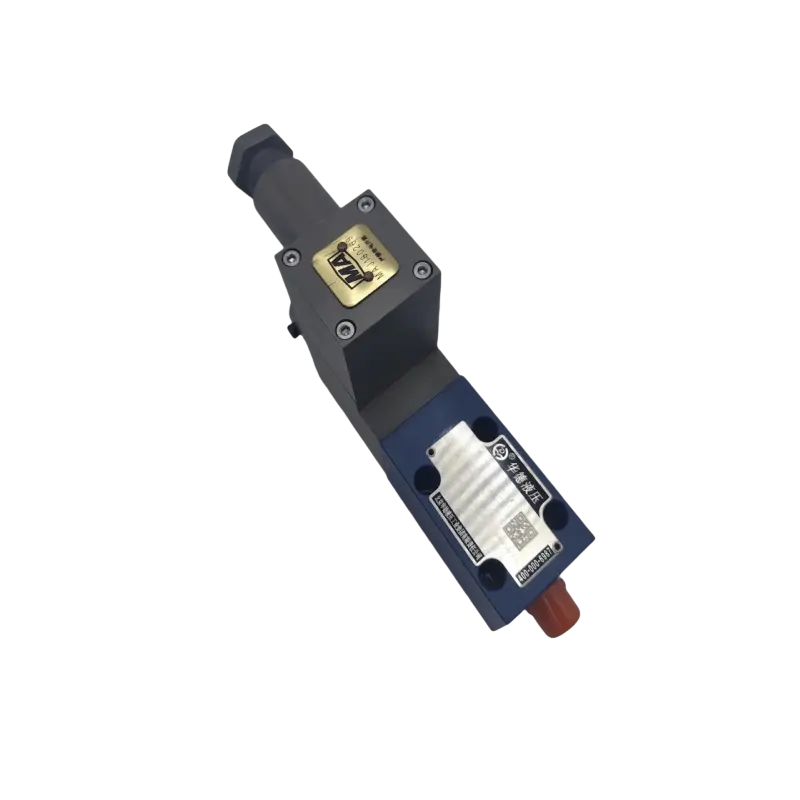

4. Gass tilbakeslagsventil

Spesielle typer for tøffe jobber

Trykkkompenserte ventiler:Disse justeres automatisk når systemtrykket endres, og holder strømmen jevn.

Temperaturkompenserte ventiler:Disse justerer for temperaturendringer som påvirker væsketykkelsen.

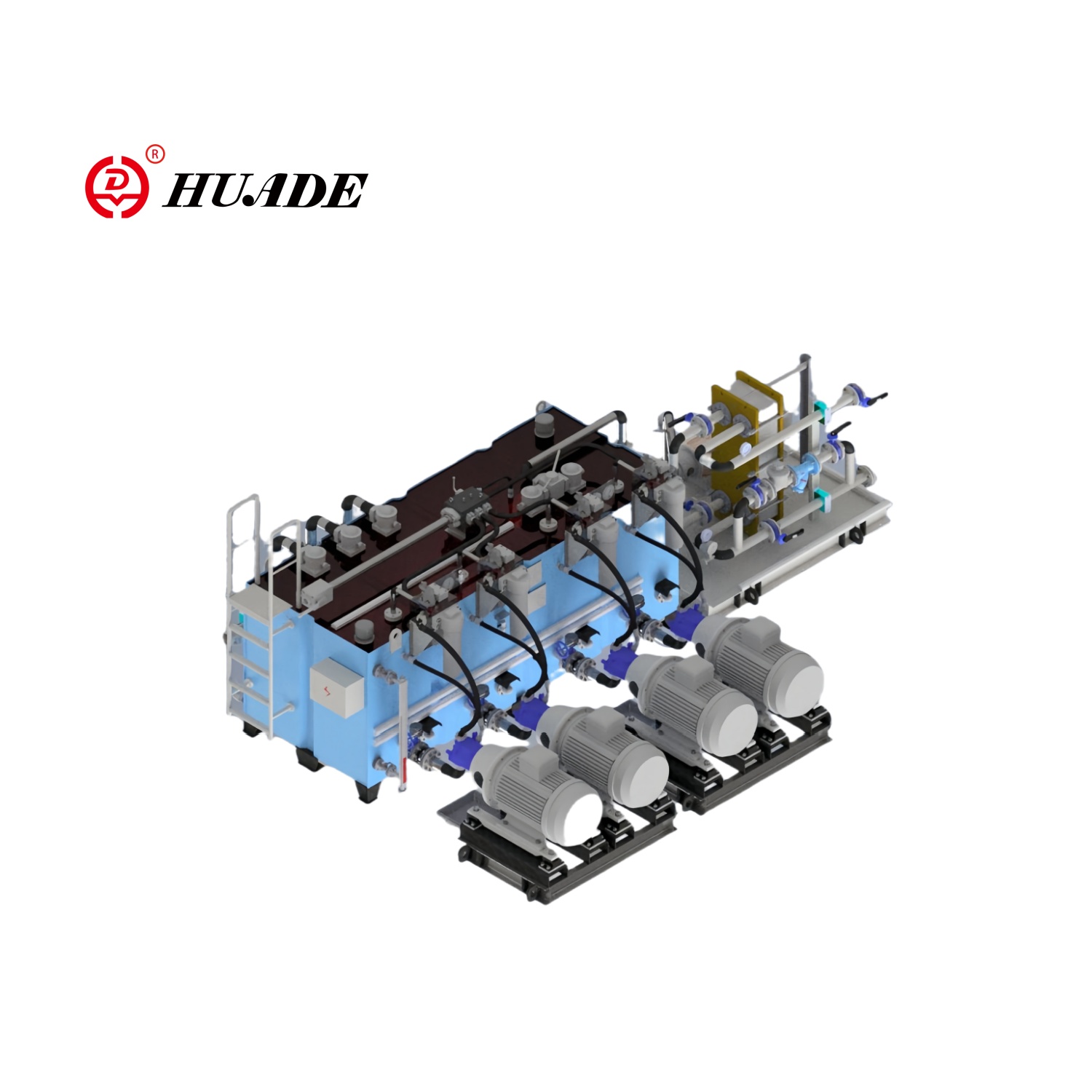

Hvor brukes hydrauliske gassventiler?

Du finner disse ventilene mange steder, sannsynligvis flere enn du er klar over:

Anleggsutstyr

- Gravemaskiner: Kontroller hvor raskt armen beveger seg opp og ned

- Bulldosere: Administrer bladets bevegelseshastighet

- Kraner: Sørg for jevn løfting og senking

Fabrikkmaskiner

- Monteringslinjer: Kontroller transportbåndets hastighet

- Presser: Administrer hvor raskt deler presses sammen

- Maskinverktøy: Kontroller skjære- og borehastigheter

Andre applikasjoner

- Kraftverk: Kontroller damp- og gassstrømmen

- Oljeraffinerier: Administrer petroleumsstrømningshastigheter

- VVS-anlegg: Styr vannføring for oppvarming og kjøling

- Testutstyr: Gi presis kontroll for materialtesting

Hvordan velge riktig gassventil

Å velge riktig gassventil er som å velge riktig verktøy for en jobb. Her er de viktigste tingene du bør vurdere:

1. Behov for strømningshastighet

- Lav strømning: Velg nåleventiler

- Høy flyt: Velg spjeld- eller eksentriske ventiler

2. Driftstrykk

- Lavt trykk: De fleste ventiltyper fungerer fint

- Høytrykk: Velg aksiale trekantede sporventiler

3. Type belastning

- Jevn belastning: Grunnleggende gassventiler fungerer bra

- Endring av last: Vurder trykkkompenserte ventiler

4. Installasjonsplass

- Trange plasser: Velg kompakt design

- God plass: Alle typer kan fungere

5. Vedlikeholdskrav

- Enkelt vedlikehold: Velg spjeldventiler

- Komplekse systemer: Kan trenge spesialiserte typer

Vedlikehold og feilsøking

Som enhver mekanisk enhet, trenger gassventiler regelmessig pleie for å fungere ordentlig.

Tips for regelmessig vedlikehold

Hold det rent

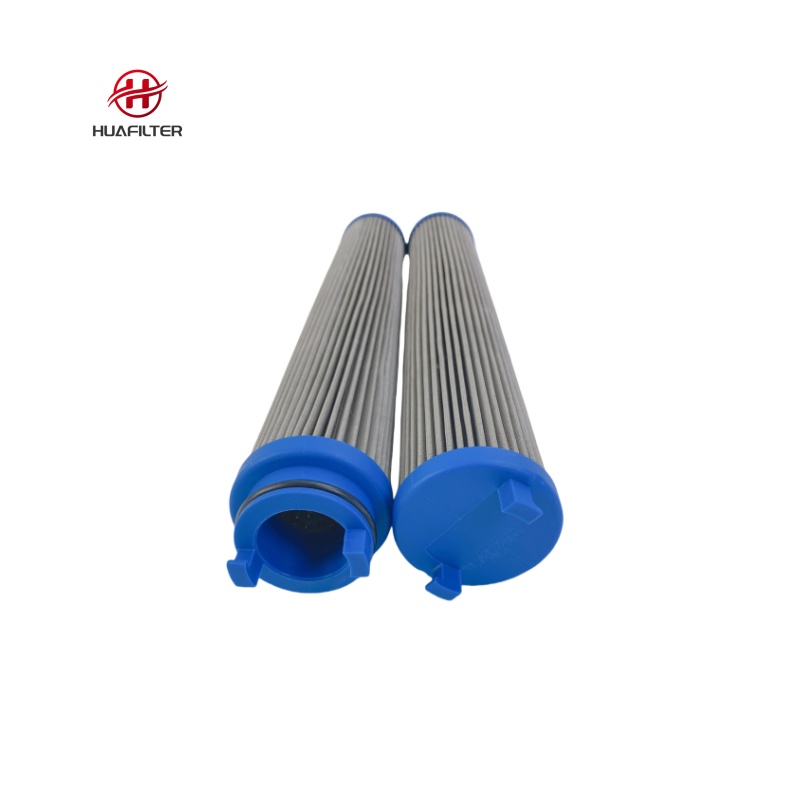

- Bruk ren hydraulikkvæske

- Bytt filtre regelmessig

- Skyll systemet med jevne mellomrom

Se etter slitasje

- Inspiser tetninger og O-ringer

- Se etter riper på ventildeler

- Skift ut slitte komponenter før de svikter

Forhindre problemer

- Hold justeringshåndtakene sikre

- Beskytt ventilene mot smuss og fuktighet

- Følg produsentens anbefalinger

Vanlige problemer og løsninger

| Problem | Hva du vil legge merke til | Sannsynlig årsak | Hva du skal gjøre |

|---|---|---|---|

| Inkonsekvent hastighet | Maskinen beveger seg ujevnt | Skitten ventil eller tett filter | Rengjør systemet, bytt filter |

| Lekker olje | Væskepytter under ventilen | Slitte pakninger | Skift tetninger og pakninger |

| Ventilen vil ikke justeres | Håndtaket vil ikke snu | Forurensning eller korrosjon | Rengjør ventilen, se etter skader |

| Merkelige lyder | Plystring eller malende lyder | Kavitasjon eller slitte deler | Kontroller trykket, skift ut slitte deler |

| Overoppheting | Systemet blir for varmt | Feil væske eller dårlig kjøling | Bruk riktig væske, forbedre kjølingen |

Forstå hydrauliske symboler

Ingeniører bruker spesielle symboler for å vise strupeventiler i hydrauliske diagrammer. Disse symbolene er standardisert over hele verden, slik at alle kan forstå dem.

Grunnleggende gassventilsymbol:Ser ut som en trekant med en pil gjennom

Justerbar gass:Har en pil som viser at den kan justeres

Gass tilbakeslagsventil:Kombinerer gass- og tilbakeslagsventilsymboler

Disse symbolene hjelper teknikere og ingeniører med å kommunisere tydelig om hydrauliske systemer.

Fordeler og ulemper

Som alt innen engineering, har gassventiler fordeler og ulemper.

Fordeler

- Enkel design - færre deler å bryte

- Presis kontroll - svært nøyaktig hastighetskontroll

- Kostnadseffektiv - relativt rimelig

- Enkel å forstå - enkel betjening

- Pålitelig - utprøvd teknologi som fungerer

Ulemper

- Energitap - skaper varme ved å begrense strømningen

- Kan bli tett - små åpninger fanger opp smuss

- Begrenset til enkel styring - ikke egnet for kompleks automatisering

- Følsom for væskerenslighet - skitten væske gir problemer

Tips for bedre ytelse

For å få mest mulig ut av dine hydrauliske gassventiler:

- Bruk ren væske - Dette er den viktigste regelen

- Dimensjoner ventilene riktig - Ikke bruk en ventil som er for stor eller for liten

- Installer bypass-filtre - Ekstra filtrering bidrar til å forhindre problemer

- Overvåk systemtemperatur - Varm væske kan skade tetninger

- Hold justeringer - Skriv ned innstillinger for forskjellige operasjoner

- Togoperatører - Sørg for at folk vet hvordan de skal bruke utstyret riktig

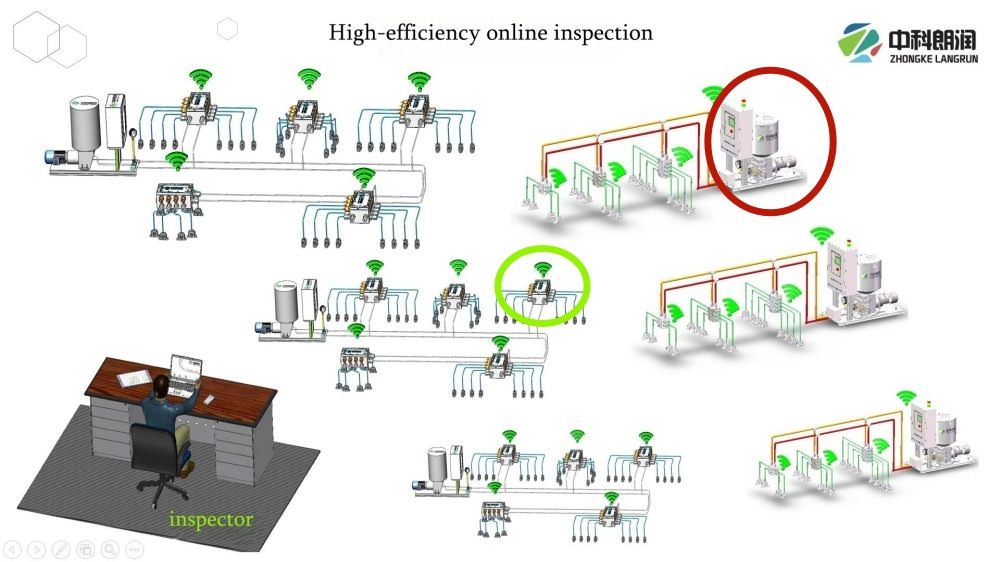

Fremtiden for hydrauliske gassventiler

Teknologien blir stadig bedre, og strupeventilene blir også bedre:

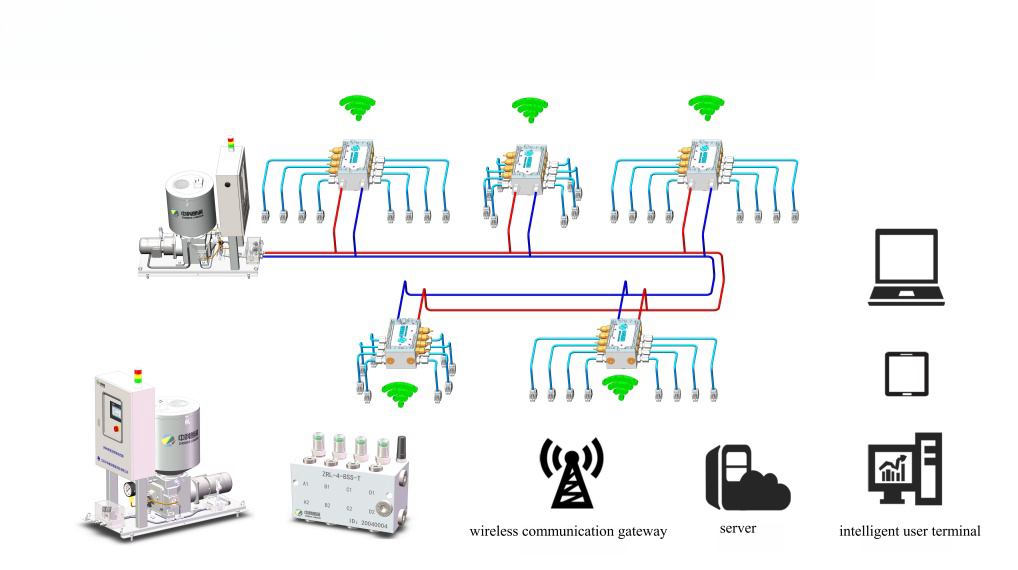

Smarte ventilermed elektroniske kontroller

Bedre materialersom varer lenger

Integrasjon med datamaskinerfor automatisk kontroll

Forbedret effektivitetfor å redusere energisvinn

Grunnprinsippet for strømningskontroll vil imidlertid alltid være viktig i hydrauliske systemer.

Konklusjon

Hydrauliske gassventiler kan virke som enkle enheter, men de spiller en avgjørende rolle for å få vår moderne verden til å fungere problemfritt. Fra gravemaskinen som graver fundamentet til fabrikkmaskinen som lager bilen din, disse ventilene hjelper til med å kontrollere bevegelse med presisjon og pålitelighet.

Å forstå hvordan de fungerer, hvor de brukes og hvordan du vedlikeholder dem kan hjelpe deg:

- Ta bedre beslutninger når du velger utstyr

- Feilsøk problemer mer effektivt

- Sett pris på ingeniørkunsten bak hverdagsmaskiner

- Kommuniser bedre med teknikere og ingeniører

Enten du akkurat har begynt å lære om hydraulikk eller ønsker å utdype kunnskapen din, husk at gassventiler er grunnleggende byggesteiner i væskekraftsystemer. Mestrer det grunnleggende, og du vil være godt i gang med å forstå mer komplekse hydrauliske konsepter.

Neste gang du ser et anleggsutstyr fungere problemfritt eller en fabrikkmaskin som fungerer med presisjon, vil du vite at et sted i det systemet gjør en hydraulisk gassventil stille og rolig jobben sin – kontrollerer flyten, styrer hastigheten og gjør alt mulig.

Trenger du hjelp til å velge riktig strupeventil for din applikasjon? Vurder å rådføre deg med en hydraulikksystemingeniør som kan analysere dine spesifikke krav og anbefale den beste løsningen for dine behov.